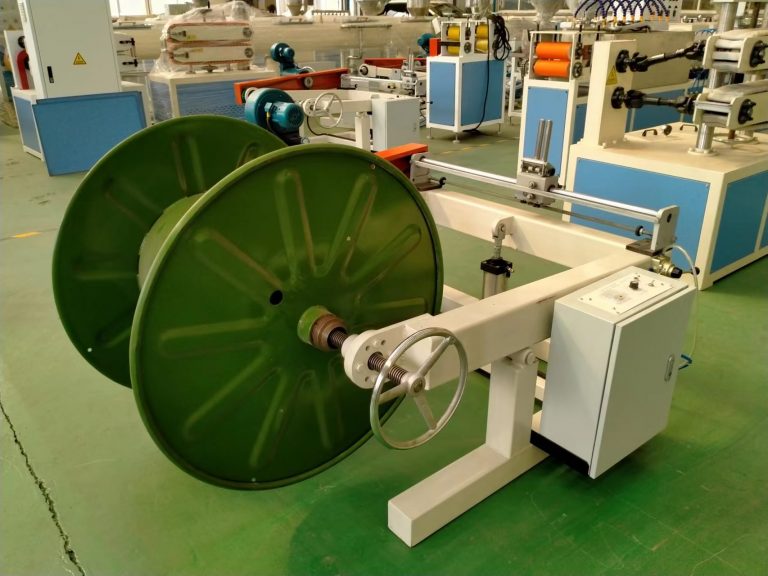

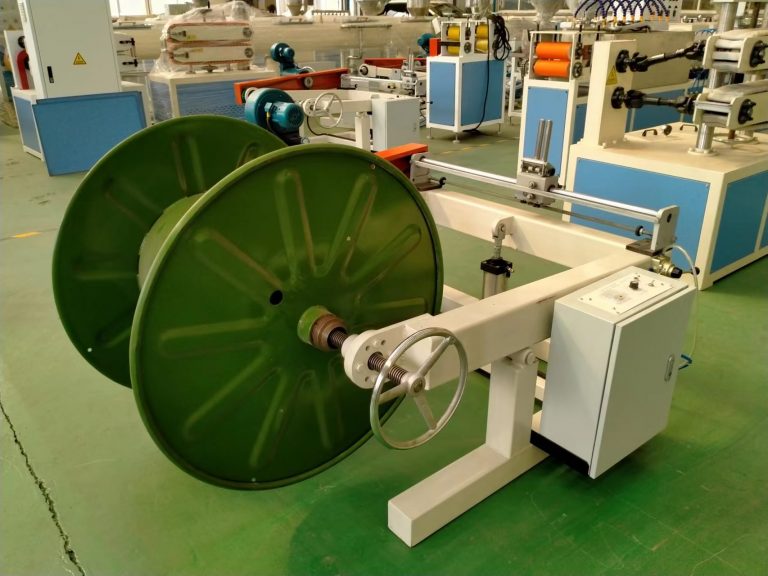

Rewinding Machine with TRAVERSE GUIDE ASSEMBLY

Heat Shrink Tubing Winding Machine winds the Heat Shrink Extruded Tube onto the iron plate. This machine is controlled by frequency conversion, coupled with the

Heat Shrink Tubing Winding Machine winds the Heat Shrink Extruded Tube onto the iron plate. This machine is controlled by frequency conversion, coupled with the

Up to 250mm Extruded Tubes, Ratio 4X. Large-scale Expandable Heat Shrink Tubing Extrusion Line. Large-scale Extruder for big-size Extruded Heat Shrink Tubing. WOLJIA designs and

The process(extrusion and expansion) of producing heat shrink heavy wall tubing consists of three steps: extrusion, electron beam irradiation, and expansion. Heat Shrink Heavy Wall Tubing

Model Selection; Single Wall Heat Shrink Tubing Extruder⇓ Single Wall Heat Shrink Tubing Extruder Equipment introduction; 1. Heat Shrink Tubing Extruder Models: SJ-30 extruder, SJ-45

The process of producing heat-shrinkable tubing consists of three steps: extrusion, electron beam irradiation, and expansion. For example, polyethylene is extruded into a tubular shape

Heat shrink busbar sleeve extrusion production line equipment introduction: 1. The extruder models are: SJ-45 extruder, SJ-55 extruder, SJ-65 extruder, SJ-90 extruder, SJ-120 extruder 2.

Thin Wall Heat Shrink Tubing Specification Range Optional Extruder Model 1. The main equipment components: heat shrinkable tube extruder – extrusion mold – cooling&shaping water

Dual Wall Heat Shrink Tubing Extruder Extrusion Line of Dual Wall Heat Shrink Tubing Extrusion is a process used to create objects of a fixed