Up to 250mm Large-scale Expandable Heat Shrink Tubing Extrusion Line

Up to 250mm Extruded Tubes, Ratio 4X. Large-scale Expandable Heat Shrink Tubing Extrusion Line. Large-scale Extruder for big-size Extruded Heat Shrink Tubing. WOLJIA designs and

Up to 250mm Extruded Tubes, Ratio 4X. Large-scale Expandable Heat Shrink Tubing Extrusion Line. Large-scale Extruder for big-size Extruded Heat Shrink Tubing. WOLJIA designs and

Heat Shrink Tubing Bag-air Expansion is generally used to expand pre-cut tubes whose walls are too thick or whose size is too large. The length

WOLJIA has extensive experience manufacturing extrusion lines to process a wide range of Fluorocarbons and High Temperature materials including but not limited to: PVDF/FEP/ETFE/PEEK/Specialty Nylons/PFA/PA

The process of producing heat-shrinkable tubing consists of three steps: extrusion, electron beam irradiation, and expansion. For example, polyethylene is extruded into a tubular shape

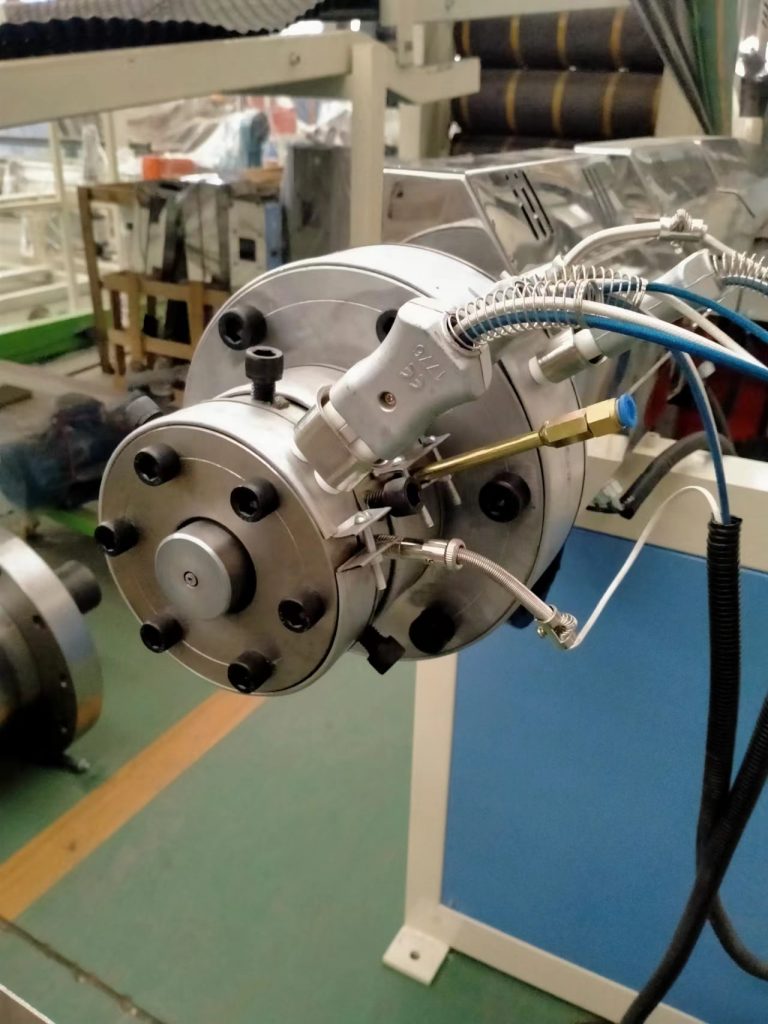

https://youtu.be/ZTPKs4Lkgf0 1. The first type of main equipment components: Heat-shrinkable tube extruder–extrusion mold–cooling and shaping water tank—roller tractor Auxiliary Machine;Winder Machine&Plying Machine, Splitter Model; SJ-45+SJ-30

A complete heat shrink tubing production line is a system that can produce heat shrink tubing from raw materials to finished products. Heat shrink tubing